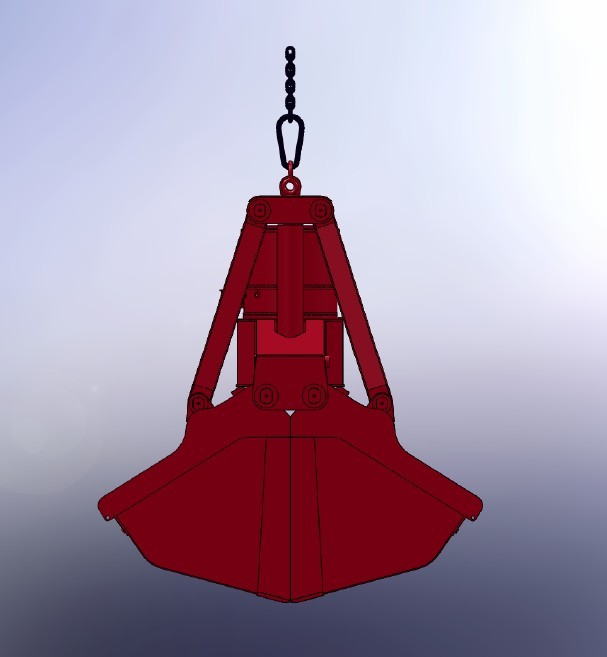

Motor Hydraulic Grab

The main advantage of clamshell motor hydraulic grab:

- Efficient improves site efficiency

- Powerful grasping ability

- High-strength materials ensure 24h durability

- Suitable for hard and harsh material

- Design various capacity from 1-40CBM

Your Best Hydraulic Grab Expert In China

Electric hydraulic grab can be divided into 2type, clamshell motor hydraulic grab and motor hydraulic orange peel grab. This is a hydraulic system with motor and hydraulic pump, which is driven by a cable reel to achieve opening and closing of the hydraulic grab bucket.

Electric Hydraulic Grab is revoluation in material handling technology, offering unmatched performance with safety benefits. When using electric grab handle materials with precision,it increased productivity and reduced material wastage compare another type grab in same time. So whether you are involved in various harsh environments,our hydraulic grab have a positive impact on your operations for handling yellow sand, coal, mineral powder, ore, cement, scrap,metal.

Technical Data

- Tab1

| Model(MHD) | Power(kw) | Deadweight

(Kg) |

SWL (t) |

Volume (m3) |

Working Pressure (bar) |

Closing time(s) | ||

| 380V 50Hz | 440V 60Hz | 380V 50Hz | 440V 60Hz | |||||

| MHD15.0-3000 |

15.0 |

18.0 |

2870 | 5.3 | 3.0 | 180 | 11 | 9 |

| MHD15.0-4000 | 3020 | 6.3 | 4.0 | 180 | 11 | 9 | ||

| MHD18.5-5000 |

18.5 |

22.0 |

3670 | 7.7 | 5.0 | 180 | 13 | 11 |

| MHD18.5-6000 | 3980 | 8.8 | 6.0 | 180 | 13 | 11 | ||

| MHD22.0-7000 |

22.0 |

26.0 |

4720 | 10.4 | 7.0 | 180 | 18 | 15 |

| MHD22.0-8000 | 5460 | 11.9 | 8.0 | 180 | 18 | 15 | ||

| MHD30.0-9000 |

30.0 |

35.0 |

6740 | 14.0 | 9.0 | 200 | 18 | 15 |

| MHD30.0-10000 | 7120 | 15.2 | 10.0 | 200 | 18 | 15 | ||

| MHD30.0-11000 | 7520 | 16.4 | 11.0 | 200 | 18 | 15 | ||

| MHD37.0-12000 |

37.0 |

44.0 |

9060 | 18.7 | 12.0 | 200 | 19 | 16 |

| MHD37.0-13000 | 9560 | 20.0 | 13.0 | 200 | 19 | 16 | ||

| MHD37.0-14000 | 10060 | 21.3 | 14.0 | 200 | 19 | 16 | ||

| MHD45.0-15000 |

45.0 |

54.0 |

11080 | 23.1 | 15.0 | 220 | 19 | 16 |

| MHD45.0-16000 | 11680 | 24.5 | 16.0 | 220 | 19 | 16 | ||

| MHD45.0-18000 | 12820 | 27.2 | 18.0 | 220 | 19 | 16 | ||

| MHD55.0-20000 |

55.0 |

66.0 |

15980 | 32.0 | 20.0 | 220 | 21 | 19 |

| MHD55.0-23000 | 16860 | 35.3 | 23.0 | 220 | 21 | 19 | ||

| MHD55.0-25000 | 17780 | 37.8 | 25.0 | 220 | 21 | 19 | ||

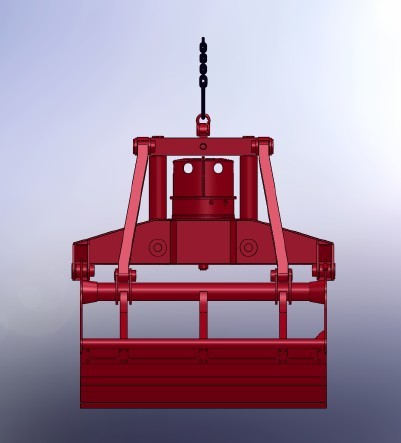

Feature And Benifit

Advanced hydraulic system of motor hydraulic grab reduces heat generation and minimizes malfunctions caused by high hydraulic system temperatures.

Strong grasping force, capable of efficiently grasping various regular and irregular materials by electric hydraulic grab.

The insertion structure of the hydraulic control valve block is convenient for maintenance of hydraulic grab.

The specially designed claw tip greatly increases wear resistance and service life of hydraulic grab.

High Quality Component

Customers who usually need to purchase electric hydraulic grab need to meet the high-intensity operation requirements of continuous operation for 24 hours, emphasizing ease of maintenance and repair. So the hydraulic system is particularly critical. GBM’s electric hydraulic grab bucket not only has low starting pressure and noise, but also runs smoothly and is easy to maintain and repair; And the failure rate is extremely low; This is because we use advanced hydraulic constant power plunger pumps, and the system pressure changes can effectively control the output of the pump, greatly improving production efficiency and energy conservation

Electric Hydraulic Grab Service

Why Choose GBM As Your Partner?

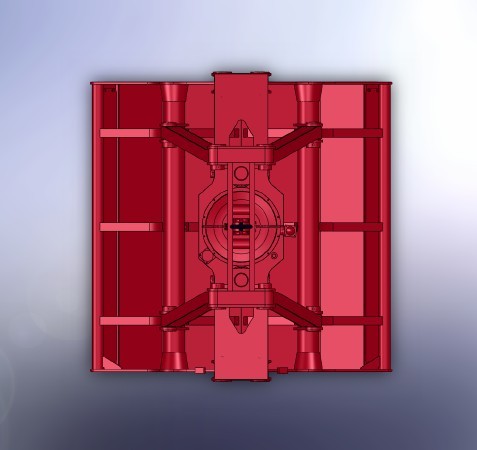

More Technical Support

- Strong Power By GBM Hydraulic Grab

- 3D Gallery

- Processing Flow

Ship Grab Global Case

Related Company Catalog

More Grab Youtube Link ,Please click below:

GBM FACTORY SUPERIOR QUALITY

Quality is the priority of enterprises, GBM accepts this strict challenge. For improve product quality, we ensure strict control from raw material storage to finished product debugging, grasping every process and detail.