What Is Belt Conveyor System?

GBM specializes in the design, manufacture, installation and operation of mobile bulk conveyor systems,main applications in ports, mining and quarry industries, yard , power plants, rail yards, steel mills, cement plants etc. The mobility solutions provided are characterized by low operating costs compared to traditional material handling methods (wheel loaders, transport trucks, fixed belt systems, etc.).and additional benefits benefits include the reduction of prior planning approvals and the high mobility,it improving user flexibility by move from site to site. We discover our mature range of belt conveying equipment,such as:

- Grasshopper Belt Conveyor

- Mobile Connecting Belt Conveyor

- Track Stacking Conveyor

- Telescopic Stacking Conveyor

- Hopper Discharging Conveyor

- Rdial Telescopic Conveyor

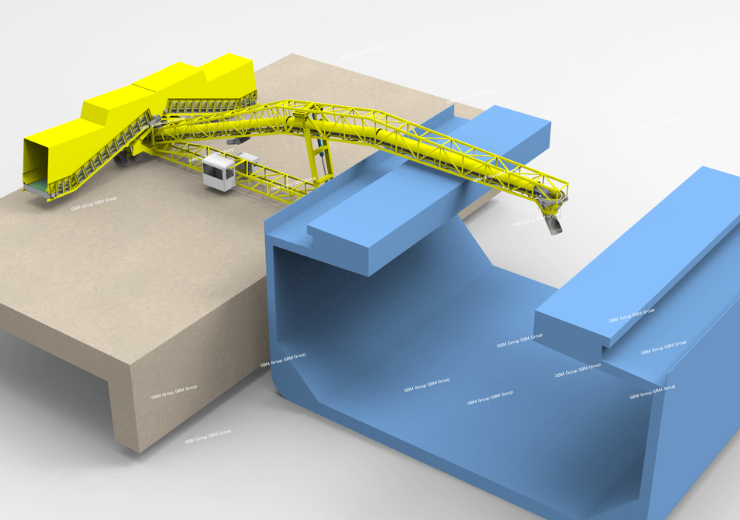

- Mobile Ship Loader

- Cambered Boom Ship Loader

Bulk Conveying System By Features

- Customize the length of the belt conveyor,enable move flexibly in and out for operation

- The adjustable discharge height enables more accurate feeding,reduce the construction of transfer station

- Convenient for movament through tail tranction

- It has automatic functions such as crawler movement, fuselage folding transportation. lifting and luffing pile height

- Customize theconveyor length,discharge height and stockpile volume,belt width etc.

- It allow directly discharge from wheel loader/crane/excavator.

- Customize based on quayside design,production rate,material density,vessel size etc.

- No civil contruction requirement and less investment compare with fixed harbour crane

- Multi function for 1 unit machine compelete ship loading,stacking and reclaiming

- Telescopic conveyor could extend and retract for max capacity and flexibility

- Stockpiling rate from 100-2000T/H,conveyor length from 25-50meter,stockpile height up to 20 meter

- 30% increase capacity compare with the typical conical stockpile

Why Choose GBM As Your Conveying System Supplier?

The reliability is first element during operation,it can bring you profitability if high efficient handling ship,we deeply understand that is main point during your purchase consideration,we could support below for your business:

- Free technical consultation for custom suitablest transfer conveyor system according to your idea

- Mature belt conveyor project oversea,and welcome for inspect

- Practical production cases and experience,enable us faster delivery

- Good steel selection for high-strength and wear-resistant materials, extend service life

- Imported component , extend service life

- In GBM, where you can find the total budget for a range of loading and unloading equipment

- We could do EPC for your whole plan

Innovation Of The Conveyor System

Delivery and Commissioning of Mobile Ship Loader

GBM continues to grow with customer demand and response the market. The production finish does not mean the end of our work, as our goal is to safely transport and install the goods to your hands perfectly.

For delivery of mobile ship loader,the belt conveyor equipemnts can be easily packed into 40ft containers and shipped directly to site, it makes very easy and cost efficient for transporting globally.All parts fully assembled and tested in our factory before dispatch,it will be correct and easily built on site shortly. Most sections are bolted together , electrics are plug and socket with an integrated hydraulicl powerpack,we will also send experienced engineer come to site for guidance and training, which eliminates any possible issues during belt conveyor installation.

Belt Conveyor Global Cases

Belt Conveyor System Application

The use of mobile systems throughout Ports and Inland Terminals is ever expanding globally. The innovative nature of the GBM ship loader means Operators have the ultimate flexible solution for handling dry bulk in the Port/ Terminal. It bring many benefits to the operation.

Track stacking conveyor is a kind of equipment more used in engineering, mainly used for loading and unloading sites often change occasions, such as station, coal yard, warehouse, construction site, sand and stone yard, farm, etc.

As a connecting conveyor, connecting each equipment of the production line, forming a material transmission system.tock yard or silo stacking for crushed stone, sand, ore; Sand and stone mine crushing plant, finished stone pile; Construction waste, soil, coal, grain and other efficient and safe storage of quarry treated stone;

- Vessel type

- cargo name

- vessel capacity

- hold quantity

- dispose angle

- total length (m)

- hold length (m)

- max size (mm)

GBM radial telescopic and luffing features of the conveyor range allows the operator full control when stockpiling a range of materials whilst eliminating segregation, degradation, contamination and compaction of material, The innovative desian allows for up to +30% arder stockbile to be achieved of in-spec material on tne same tootprint wnen compared to a standard convevor desion or tne same length. The conveyor moves from left to right in a radial arc motion starting at a low luffing angle with the inner conveyor extracted. When the unit completes a full pass over the stockpile, the inner convevor extends and continuous to radial over the stockpile. The luffing angle automatically increases as the stockpile height increases.

Site assembly usually takes 1 month to implement. Our service engineers can provide onsite equipment empty machine and load operation and user training. As part of the field service program, our engineers can also provide field support for your equipment to ensure uptime and production.