ECO HOPPER

The main advantage of Eco Hopper:

- 99% Excellent dust removal effect

- Easy operation&Maintenance

- High mobility, self-walking function

- Independent generator power supply

- Unloading high efficiency

- Competitive price with high configuration

First Eco-Hopper Manufacturer In China

GBM®Eco-hopper is mainly used for unloading of bulk cargo,the bulk cargo is grabbed by the gantry crane or vessel,then unloading to eco-hopper bucket,the dust collector of the eco hopper starts filtering the generated dust at this time.

Technical Data

- tab1

| NO. | Hopper Model | Hopper Volume | Rated capacity | Dead Weight | Feed Port Size | Total power | Truck Height | Discharge Dimension |

| (m3) | (t/h) | (kg) | (mm) | (KW) | (mm) | (mm) | ||

| 1 | HP30 | 30 | 600 | 26500 | 5000*5000 | 15KW | 4000mm | 800*800 |

| 2 | HP50 | 50 | 600 | 34500 | 6000*6000 | 15KW | 4000mm | 800*800 |

| 3 | HP70 | 70 | 800 | 45320 | 7000*7000 | 15KW | 4000mm | 1000*1000 |

| 4 | HP90 | 90 | 800 | 52500 | 8000*8000 | 15KW | 4000mm | 1000*1000 |

| 5 | HP110 | 110 | 1000 | 60350 | 8000*8000 | 20KW | 4000mm | 1200*1200 |

Pulse Type Bag Filter Of Eco hopper

1. High dust removal efficiency: The dust removal efficiency of bag filters is very high, usually reaching over 99%, and can capture small dust particles with a particle size greater than 0.3 microns.

Telescopic Chute Of Eco Hopper

1.The telescopic chute automatically adjusts the height of the bottom dust-proof skirt according to the height of the material pile through an intelligent control system and sensor, maintaining a suitable distance from the material pile and effectively preventing the dust generated by material impact on the material pile from overflowing.

2.The telescopic chute adopts a double-layer structure, the chute is made of wear-resistant steel,and the material unloading onto the truck is through the internal chute, while the outer layer is wrapped with wear-resistant cloth, the dust generated during unloading is collected upward by the dust collector through the middle of internal chute and outer layer.

This design is suitable for eco hopper truck discharing area to reduce dust pollution.

Walking Mechanism Of Eco Hopper

The eco hopper adopts a wheeled walking mechanism, which is the most common type of walking mechanism and suitable for flat ground.

The self-walking eco hopper are equipped with 2 driving wheels and 2 driven wheels. The driving wheel is powered by an electric motor and driven by a gear chain, while the driven wheel is equipped with a steering cylinder for steering and powered by hydraulic station.

The normal walking eco hopper is equipped with 2 driven wheels and 2 fixed wheels. The eco hopper is equipped with a towing mechanism, which is connected to loader or trailer for walking/turning.

Why Choose GBM As Your Partner?

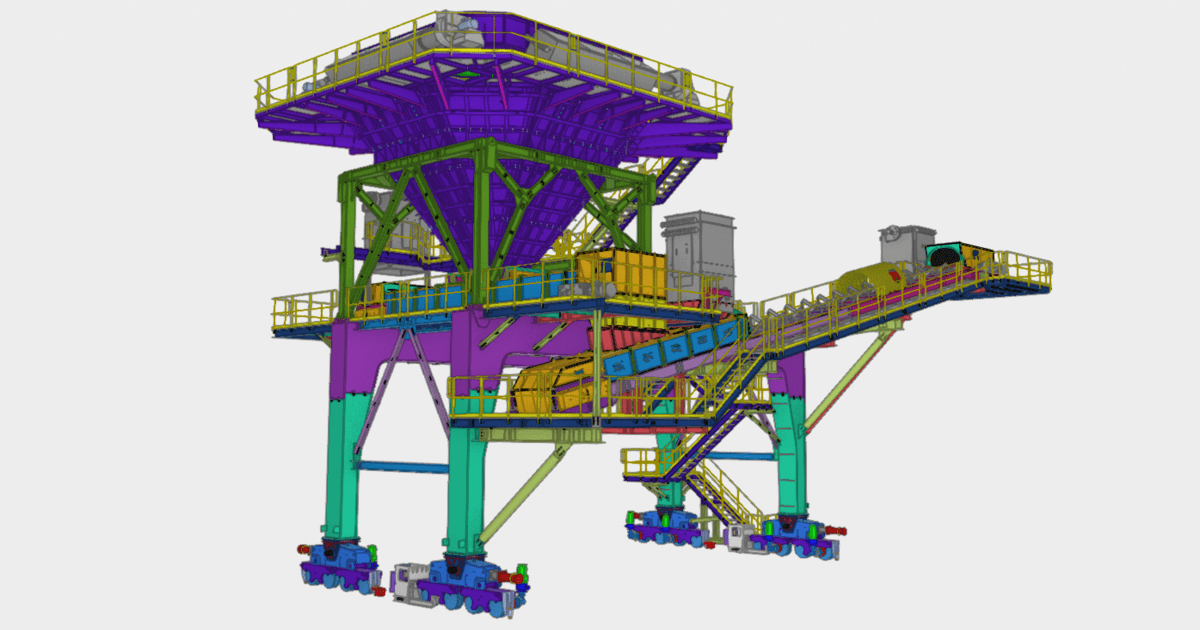

Eco Hopper Technical Gallery

- Eco Hopper Unloading Cement Without Any Dust

- 3D Gallery

- Processing Flow

Eco Hopper Global Case

Related Company Catalog

More Eco hopper Youtube Link ,Please click below:

- Unloading cement by GBM Eco hopper in the Philippines without any dust

- Unloading clinker by GBM Eco hopper in the Kribi without any dust

- Unloading cement by GBM Eco hopper in the Gambia without any dust

- The production process, welding quality, and quality inspection of Eco hopper

- Proffestional Packing details for eco hopper delivery

- GBM ecological hopper and diesel grab working at Japan site

- Preparation before shipment for dust-proof hopper at factory

GBM FACTORY SUPERIOR QUALITY

Quality is the priority of enterprises, GBM accepts this strict challenge. For improve product quality, we ensure strict control from raw material storage to finished product debugging, grasping every process and detail.