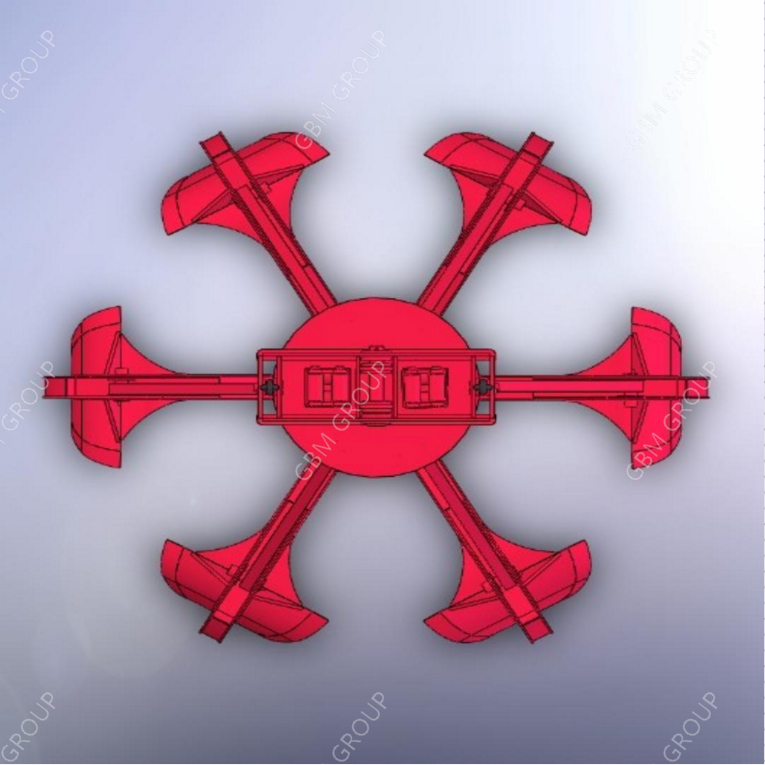

Orange Peel Hydraulic Grab

The main advantage of orange peel motor hydraulic grab:

- Meet the application for the special shape block material, scrap and scrap metals handling efficiently.

- Powerful grasping ability

- High-strength materials ensure 24h durability

- Design various capacity from 1-20CBM, peels 3-8 ps and more

Your Best Orange Peel Hydraulic Grab Expert In China

The Electric Hydraulic Orange Peel Grab mainly designed for handling bulk materials in blocks, particles, bagged and irregular shapes, such as coke, pig iron, metal scrap, slag, garbage and rock etc., it’s widely used on ports, steel plants and garbage treatment plants, match with tower cranes, ship unloaders, travelling cranes and other type of cranes.

the grab has its own hydraulic system, all key elements are imported well-known brands to ensure high performance and long lifetime. it’s simple in structure and easy to operate.

Hydraulic Turning points according to the customers’ requirement, excavator grab without rotary use the oil cylinder or standby pipeline, no need to add other hydraulic valve block and pipeline. Rotary hydraulic excavator grab need to add another set of hydraulic valve and pipeline to control, oil cylinder is equipped with the piston protective device, HARDOX plate is adopted for the key parts.

Technical Data

- Tab1

| Model(steel) | Power(kw) | Deadweight(Kg) | SWL(t) | Volume (m3) | W/Pressure(bar) | Close time(s) | ||

| 380V 50Hz | 440V 60Hz | 380V 50Hz | 440V 60Hz | |||||

| MHM15.0-3000 | 15.0 | 18.0 | 1410 | 2.5 | 0.35 | 180 | 8 | 6.5 |

| MHM22.0-800 | 22 | 26 | 2960 | 6.0 | 1.0 | 180 | 11 | 9 |

| MHM30.0-1250 | 30 | 35 | 4270 | 7.8 | 1.25 | 180 | 14 | 12 |

| MHM37.0-2000 | 37 | 44 | 5980 | 12.2 | 2.0 | 200 | 15 | 13 |

| MHM45.0-3200 | 45 | 54 | 8280 | 18.0 | 3.2 | 200 | 20 | 17 |

| MHM55.0-7000 | 55 | 66 | 10600 | 31.6 | 7.0 | 220 | 26 | 22 |

| Model(Rubbish) | Power(kw) | Weight(kg) | SWL(t) | Volume(cbm) | Pressure(bar) | Open time(s) | Closetime(s) | Cylinder |

| MHM18.5-4000 | 18.5 | 3110 | 6.7 | 4 | 180 | 7 | 11.5 | 80×390 |

| MHM30.0-6300 | 30 | 4800 | 7.7 | 6.3 | 180 | 7.5 | 13.5 | 90×500 |

| MHM37.0-10000 | 37 | 6900 | 15.2 | 10 | 200 | 11 | 19 | 125×500 |

| MHM45.0-12000 | 45 | 7490 | 17.1 | 12 | 200 | 14.5 | 17 | 125×500 |

| Model(Excavator) | Weight(Kg) | Weight(Kg) | Weight(Kg) | Volume(cbm) | Peels | SWL crane(t) | ||

| Close | Semi-close | Open | ||||||

| HMG330-1 | 1010 | 930 | 900 | 0.4 | 5 | 7-10 | ||

| HMG500-1 | 1240 | 1140 | 1060 | 0.5 | 5 | 10-12 | ||

| HMG800-1 | 1960 | 1850 | 1700 | 0.8 | 5 | 17-20 | ||

| HMG1250-1S | 3020 | 2830 | 2700 | 1.25 | 6 | 30-40 | ||

| HMG2000-1S | 3320 | 3040 | 2860 | 2.0 | 6 | 50 | ||

Meet Most Demanding Applications

Orange peel Hydraulic grab are among the most robust on the market. The constructive geometry and the long levers of the tines grant an enormous clamping force. Bushings and pins are oversized. Cylinders are hydraulically cushioned. The solid end stops, both in opening and closing, divert the most violent blows on the massive frame. The assembly is very precise and accurate. The combination of these features makes this line suitable to the most modern and high-performance material handlers.

Versatility

Orange peel hydraulic grab are multi-tines gripping devices. Each tine is set in motion by hydraulic cylinder. For that the jaws, or teeth, have a synchronized, but independent, movement of opening and closing. The number of tines vary from three to eight. This feature makes polyp grapples particularly suitable for the collection and handling of large quantities of bulk materials such as metal scrap, paper, tires drive, solid urban waste and firewood. They can be mounted on truck cranes, mini excavators, stationary cranes, hydraulic excavators and wheeled loaders.

High Quality Components

All hydraulic orange peel grab are built using high-tensile qualified steel for the structural parts and use wear plates (Hardox) for parts in contact with the handled materials, such as the blades of the buckets, the tines and the tips. The large diameter pins are made of special steel, hardened under heat treatment. The bushes are provided of an internal spiral for the distribution of grease. The entire production cycle is certified according to ISO standards.

Why Choose GBM As Your Partner?

More Technical Support

- Production Process Of Hydraulic Orange Peel Grab

- 3D Gallery

- Processing Flow

Hydraulic Grab Global Case

Related Company Catalog

More Hydraulic Grab Youtube Link ,Please click below:

GBM FACTORY SUPERIOR QUALITY

Quality is the priority of enterprises, GBM accepts this strict challenge. For improve product quality, we ensure strict control from raw material storage to finished product debugging, grasping every process and detail.