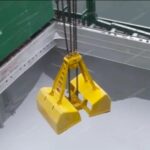

Mechanical Grab

The Key Advantages of Mechanical Grab

- Completely operating with mechanical Configuration

- Adapt for multiple materials

- Clamshell or multi pin bucket optionally

- compatible to types of crane

- Durable and low maintenance

- Various volume Customizable

Your Best Mechanical Grab Expert In China

GBM® Grab Mechanical grabs being most effective handling for bulk materials, scraps, slurry on vessel cranes or portal cranes.According to the material feature and various leak-proof structure, by the material features and application, the bulk clamshell grabs with capacity from 1-50cbm for handling the material such as grain, gravel, fertilizers, wood chips, nickel ore, iron ore, pellets, biomass and etc., the dredging grabs could be for slurry cleaning in the water, the multi pin grabs could be for scrap, scrap metals handling.

Nowadays, the mechanical grab buckets are the regular type of grabs used in different industries, it could match with each types of crane, without power or hydraulic energy required.It is easy to operate and comes with comfortable and efficient using.

Technical Data

- Mechanical Clamshell Grab

| Model | SWL(t) | Dead weight(kg) | capacity (m3) | Wire rope diameter(mm) | Pulley diameter (mm) | Pulley Rate |

| GBMFRB5-1.0-2.5 | 5 | 2500 | 2.5 | 18 | 355 | 4/5 |

| GBMFRB7.5-1.2-3.5 | 7.5 | 3300 | 3.5 | 20 | 400 | 4/5 |

| GBMFRB10-1.5-4.0 | 10 | 4000 | 4.0 | 22 | 450 | 4/5 |

| GBMFRB20.0-2.0-6.5 | 20 | 7000 | 6.5 | 26 | 560 | 4/5 |

| GBMFRB35.0-2.5-10.0 | 35 | 10000 | 10 | 32 | 630 | 4/5 |

| GBMWTM6.0-2.0-1.5 | 6 | 3000 | 1.5 | 16 | 315 | 3/4/5 |

| GBMWTM10.0-2.0-2.5 | 10 | 5000 | 2.5 | 20 | 400 | 3/4/5 |

| GBMWTM16.5-2.5-4.0 | 16.5 | 6500 | 4.0 | 24 | 500 | 3/4/5 |

| GBMWTM33.0-2.5, 1.0-8.0 | 33 | 13000 | 8.0 | 32 | 630 | 3/4/5 |

| GBMWTB25.0-1.8-6.0 | 25 | 14200 | 6.0 | 40 | 880 | 5 |

| GBMWTB32.0-2.0-8.0 | 32 | 16000 | 8.0 | 42 | 900 | 5 |

| GBMWTB80.0-2.0-18.0 | 80 | 44000 | 18.0 | 52 | 1050 | 5 |

Feature And Benifit

Energy saving: GBM ® Mechanical Clamshell Grab only adopt the mechanical structure to operate the buckets for the material handling, without energy power consumption during operation

Safe and reliable: GBM ®mechanical grab is directly operated with the wire ropes from the crane without any additional cables required.

Less maintenance: the grab is just the mechanical parts integrated, no electrical or hydraulic components be required, much less the time and cost on maintenance.

Operation Flexibly

Various applications: GBM ®Mechanical grabs by the buckets different designing, it could be used for the bulk material handling, scrap/scrap metal handling, slurry or dense sands dredging in the river or seabed.

Large volume: GBM ® could design in large capacity, up to 30CBM. specially for the dredging grab could be as large as 30CBM, the multi-pin grab could be 10 fingers.

High efficiency: GBM ® mechanical grab operated flexibly, it could be open or close as the time required, it could save the time compare with the Electric-Hydraulic Grab, which can be closed at full open.

Top Quality and Service

GBM provides the customized designing, fabrication with Top quality, anyway the standard we are following ISO, and the fabrication by skilled workers and the supervision by the special qualified inspector, who always keep on site with the workers, to supervise each details.

the raw materials are always used with top quality, and certified with quality license.

our services team are always ready for flying to any site which there is any support required.

Why Choose GBM As Your Partner?

Mechanical Grab

- For More Wire Rope Grab Videos

- 3D Gallery

- Processing Flow

Mechanical Grab Global Case

Related Company Catalog

More Grab Youtube Link ,Please click below:

GBM FACTORY SUPERIOR QUALITY

Quality is the priority of enterprises, GBM accepts this strict challenge. For improve product quality, we ensure strict control from raw material storage to finished product debugging, grasping every process and detail.