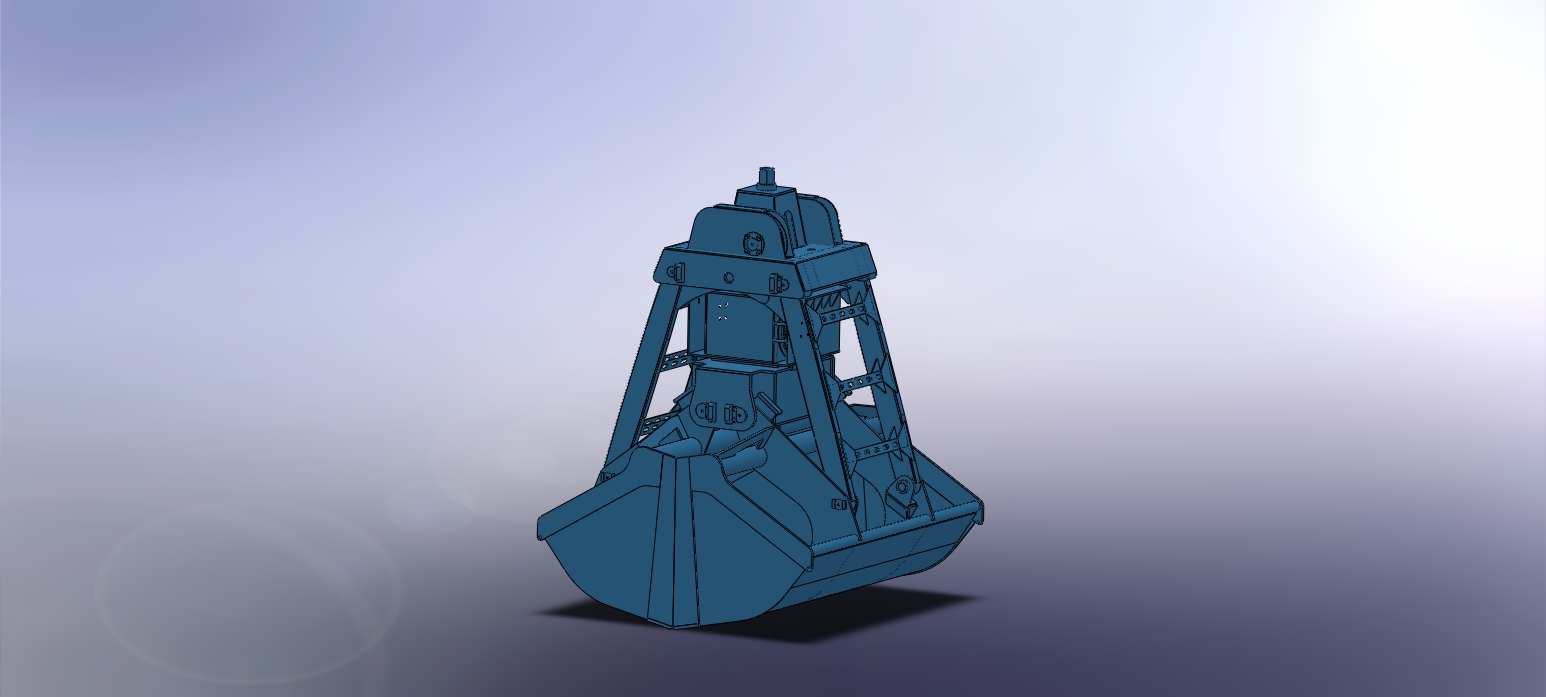

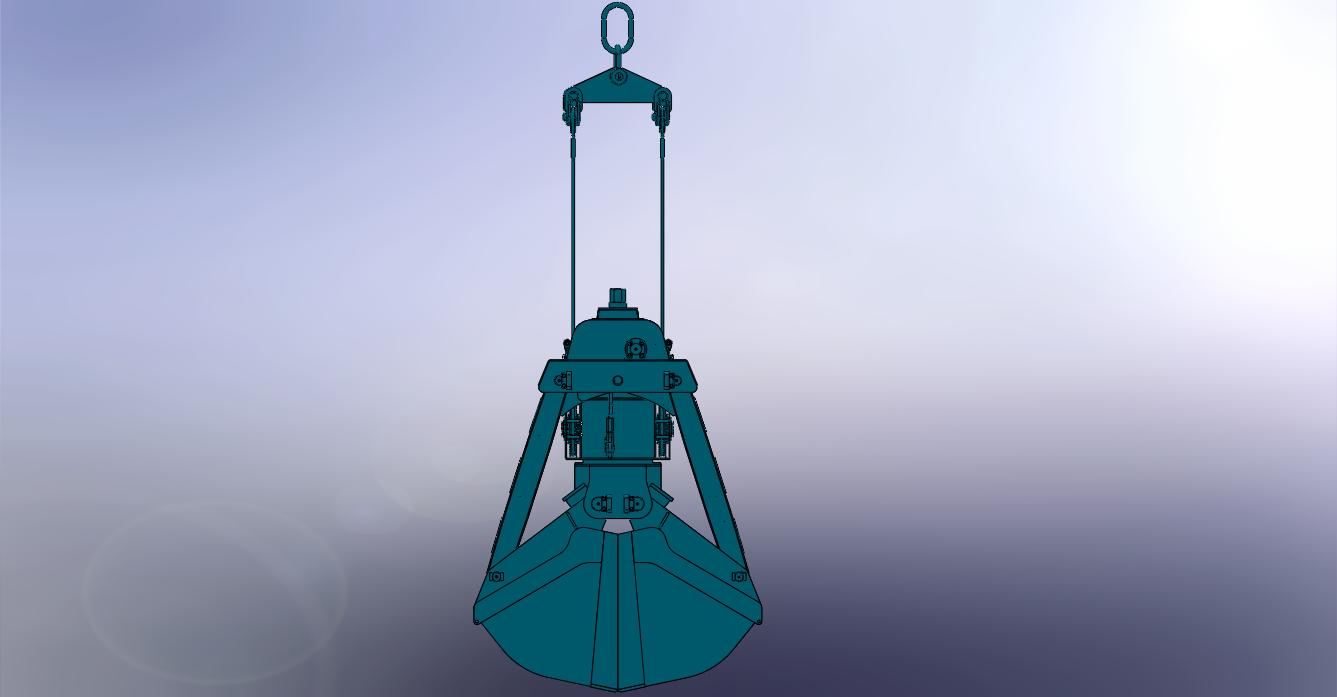

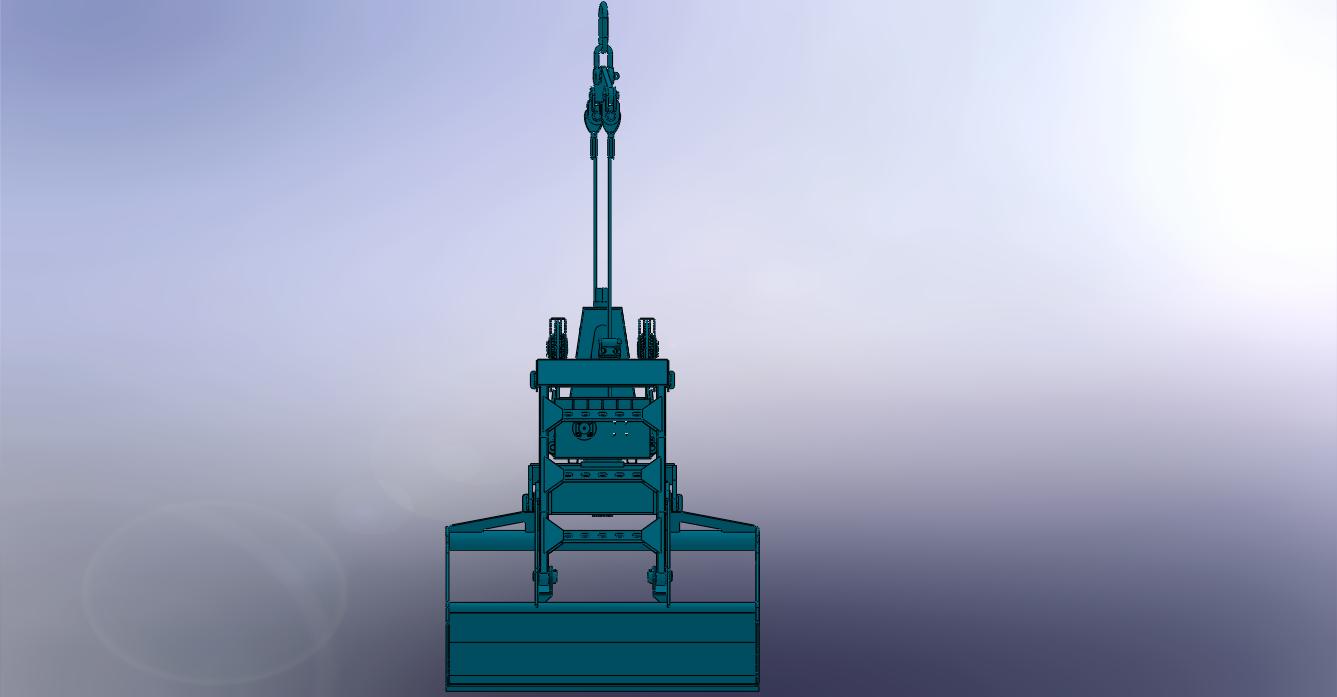

Remote Control Grab

The main advantage of clamshell wireless remote control grab:

- No extra power for energy saving

- Adapt for multiple materials

- Easy operation for handling

- Easy fitting to the crane

- Long service life of hydraulic system

- Safe and reliable

Your Best Grab Expert In China

GBM® Grab remote control grabs being most effective handling for bulk materials on vessel cranes or portal cranes.According to the material feature and various leak-proof structure,we offer a wide remote control grab capacity from 1-50cbm such as grain, gravel, fertilizers, wood chips, nickel ore, iron ore, pellets, biomass and etc.

Nowadays, wireless remote-control grab buckets become the most popular type of ship grab because operators only use a remote control transmitter (hand unit) to work, without power cables on cranes Crane.It is very simple and comes with comfortable and efficient using.

Technical Data

- Tab1

| Model | SWL(t) | Dead weight(kg) | capacity (m3) | Wire rope diameter(mm) | Pulley diameter (mm) | Pulley Rate |

| GBMRCB10.0-1.0-5000 | 10 | 5000 | 5 | 24 | 520 | 3 |

| GBMRC10.0-1.5-6000 | 16 | 6200 | 6 | 28 | 520 | 3 |

| GBMRC20.0-1.5-8000 | 20 | 8000 | 8 | 28 | 520 | 3 |

| GBMRC28.0-2.0-9000 | 28 | 9800 | 9 | 36 | 650 | 3 |

| GBMRC40.0-2.5-10000 | 40 | 15000 | 10 | 40 | 810 | 3 |

| GBMRC10.0-1.5, 1.0-3300.5000 | 10 | 5000 | 3.3-5.0 | 24 | 520 | 3 |

| GBMRC16.0-1.6 0.8-5000,8000 | 16 | 7000 | 5.0-8.0 | 28 | 520 | 3 |

| GBMRC20.0-2.0, 1.0-6000.10000 | 20 | 8000 | 6.0-10.0 | 28 | 520 | 3 |

| GBMRC25.0-2.5, 1.0-6000.12000 | 25 | 9500 | 6.0-12.0 | 36 | 650 | 3 |

| GBMRC28.0-2.5, 1.0-8000.14000 | 28 | 10500 | 8.0-14.0 | 36 | 650 | 3 |

| GBMRC36.0-1.6, 1.0-13000,20000 | 36 | 14800 | 13.0-20.0 | 40 | 810 | 3 |

| GBMRC40.0-1.6, 1.0-15000,22000 | 40 | 16000 | 15.0-22.0 | 40 | 810 | 3 |

Feature And Benifit

Energy saving: GBM ® remote control grab only needs small pulse electricity by solenoid valve Comparing with electric hydraulic grab,it requires large of electricity consumption during operation

Safe and reliable: GBM ®remote-control grab is directly hung on the crane without any other accessories, and the rotation won’t affect its use

Convenient to use: For manual grab,it required operator drags a steel wire rope to control open and close.Comparing with GBM ®remote grab,the operator only needs to operate by small remote control just like pressing the TV remote control.

Perfect Grab For Bulk Commodity

Strong functionality: GBM ®remote control graph can be opened in any angle, which are beneficial for loading and unloading trucks/hoppers with small openings limit.

Large volume: GBM ® could design in large capacity, up to 50CBM.Comparing with manual grab,no need worry the break of opening and closing mechanism.

High efficiency: GBM ®remote grab could open directly,It reducing the shake to crane, and shortening the working time. Comparing with mechanical grab,it must be lowered onto the material to touch open.

Remote Grab Service

In any of cases, GBM® have an independent installation service department team is available which set for assembly installation,training and after-sales service.

This applies to train your crews if they are unfamiliar with the provided grabs.

If vessel calling China,GBM® team would come to your designated shipyard,provide your crews theoretical and practical training during commissioning ,which it is free of charge.

Why Choose GBM As Your Partner?

View More About GBM Remote Grab

- Wireless Remote Control Grab At Vessel

- 3D Gallery

- Processing Flow

Ship Grab Global Case

Related Company Catalog

More Grab Youtube Link ,Please click below:

- GBM REMOTE CONTROL GRAB Working Process At Vessel

- GBM REMOTE CONTROL GRAB Heavy Load Test At Our Factory

- Leak-Proof Remote Grab Ready To Delivery At GBM Factory

- GBM Processing Equipment And Details To Ensure Quality

- Clamshell Ship Vessel Grab Factory Tour

- GBM 24set REMOTE CONTROL GRAB Production At Factory

GBM FACTORY SUPERIOR QUALITY

Quality is the priority of enterprises, GBM accepts this strict challenge. For improve product quality, we ensure strict control from raw material storage to finished product debugging, grasping every process and detail.